Larrivée Terms and Acronyms

|

This is a wiki page. That means that you can edit it. If you prefer not to do that, please post suggestions in the Discussion about acronyms on the Larrivée Forum where Forum members have suggested terms and definitions -or- add a note in the discussion page for this article For more general Larrivée information see: Larrivée Guitars |

Terms and Acronyms

|

Acronym / Term |

Meaning |

| ADI | Adirondack Spruce top (example) |

| BB | Bubinga |

| BC | Bear Claw |

| BR | Brazilian Rosewood |

| BZ | Brazilian Rosewood |

| CE | Collectors Edition |

| CNC | Computer Numerical Control machine |

| D, DRED | Dreadnought Body Style |

| EI | Elephant Ivory |

| EIR | East Indian Rosewood |

| EIRW | East Indian Rosewood |

| EJ12 | D'Addario EJ Medium (80/20 Bronze) |

| EXP | D'Addario EXP 17 Strings |

| FM | Flamed Maple top wood, bindings |

| FMI | Fossilized Mammoth Ivory |

| FWI | Fossilized Walrus Ivory |

| GAS | Gear Acquisition Syndrome Guitar Acquisition Syndrome |

| HK | Hawaiian Koa top, back and sides |

| Hog | Mahogany top, back and sides |

| IR |

Indian Rosewood Infra-red |

| IS | Italian Spruce Top Wood |

| JCL | Jean Claude Larrivée |

| Koa | Hawaiian Koa top, back and sides |

| L | L (Larrivée) Body Style |

| LS | Larrivee Small Body |

| MADI | Madagascar Rosewood (example) |

| MAP | Minimum Advertised Price |

| MH | South American Mahogany |

| MR | Madagascar Rosewood |

| MSRP | Manufacturers Suggested Retail Price |

| MT | Mahogany Top |

| NGD | New Guitar Day |

| OHSC | Original hard shell case |

| OM | Orchestra Model Body Style |

| OMV | Orchestra Model with Venetian Cutaway |

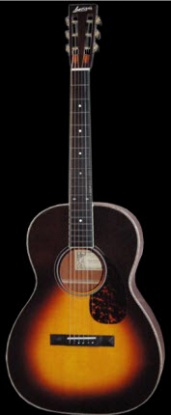

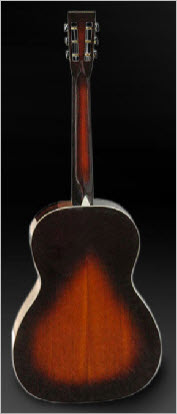

| OO | OO Body Style |

| P | Parlor Body Style |

| PB | Phospher Bronze (strings) |

| QM | Quilted Maple top wood |

| RW | Rosewood |

| SBT | Sunburst Top |

| SD |

Slope Shoulder Dreadnought

Body Style (Larrivée Traditional Series) |

| SH | Slotted Headstock |

| Sitka | Sitka Spruce top wood |

| SO |

Silver Oak, Silky Oak Special Order |

| SP |

Sapele Martin SP Studio Performance Series Strings Street Price |

| TSB |

Full

Tobacco Sunburst (term

as used on the Larrivée site) Total Sunburst (back and sides included) |

| WAHI | West African Ivory Saddle |

Tonewoods References

Truss Rod Wrenches

Notes from the Larrivée Frequently Asked Questions

Warning: VERY IMPORTANT

Never tighten the truss rod more than 1 full turn from the loose position. If at all possible, have a professional do the job for you.

Where is the truss rod?

Our truss rod is located on the inside of the guitar, where the neck joins the body. You can see it by sticking a small mirror (Like a woman's compact) inside the guitar and looking up under the fingerboard. There is a little hex connector there where the truss rod adjustment key fits.

How do I use the truss rod?

If at all possible, have a professional do this, or have them show you how. However, if you are set on doing this yourself, please follow these instructions.

- If your guitar has too much front bow in its neck and you're trying to flatten its neck, tighten the truss rod (No more than 3/4 of a turn.)

- If your guitar has a back bow and you're trying to flatten it, loosen the truss rod.

VERY IMPORTANT

Never tighten the truss rod more than 1 full turn from the loose position. If at all possible, have a professional do the job for you.

What is the truss wrench size?

We have two wrenches, depending when your guitar was manufactured. The newer style truss rod uses a wrench that is silver, shaped like an L and measures 5/32nds. The older style wrench is black, shaped like a J and measures 3/16ths.

Where to buy

Available from Cherokee Guitar Company

Two styles

|

Old Style

|

New style |

|---|---|

Cutaways

Florentine |

Venetian |

Slotted Headstock

Larrivée History

(Sources include Larrivee's website, WikiPedia, and Larrivee customer service emails.)

- 1967: An old house in Toronto, ON, Canada

- 1968-71: Basement of Jean’s Townhouse in Toronto, ON, Canada

- 1971-72: Above the Tarragon Theatre in Toronto, ON, Canada

- 1971: First steel-string guitar

- 1972-73: Storefront on Mount Pleasant in Toronto, ON, Canada

- 1973-75: Portland Street Shop in Toronto, ON, Canada

- 1975-77: Dwight Street in Mimico, Toronto, ON, Canada

- 1976: 8 people, 25-30 guitars/month

- 1977-82: Esquimalt Shop, Victoria, BC, Canada

- 1977: 14 people, 4 guitars/day

- 1982-92: 267 E. 1st Street Shop in North Vancouver, BC, Canada

- 1983: First solid-body electric

- 1984: switched from hot lacquer to catalyzed modified polyurethane finish

- 1989: First use of CNC

- 1991: 11,000 sq ft, 35 people, 25 guitars/day

- 1993-98: Victoria Diversion shop in Vancouver, BC, Canada

- 1993: 50/60/70 series introduced with large sound holes, 383 built

- 1995: switched from polyurethane to McFadden UV polyester finish

- 1996: 50 people, 20 guitars/day

- 1997: 60 people, 40 guitars/day

- 1997: D-Lite, D-03 introduced

- 1998-Present: Cordova Street Factory in Vancouver, BC, Canada

- 1998: 33,000 sq ft in Vancouver, 100 people, 60 guitars/day

- 2001-Present: Yarnell Place Factory in Oxnard, CA, USA

- 2010: switched from McFadden UV polyester to a new dual-cured finish (partial catalyzation with cobalt & peroxide, and UV light)

- 2010: went to a stacked heel with the -03 series, then reintroduced the -02 series with stacked heel, and went back to one-piece necks for the -03 series

Ongoing discussion on the Larrivee Guitar Forum

California

- Virtually all gloss guitars have been made in california since 2001. From 2001 to 2003 many of the bodies were made in Canada and then completed in America. The first truely completely American Made Larrivee is an L-09 with Serial #80000 which resides in the Larrivee Collection for sentimental purposes.

- While there are some parts that made or shaped by CNC, I wouldnt nessesarily call that automation. There are no robots assembling parts, or spraying finishes, or buffing. There are no conveyor belts moving instruments from one step to another. The work is all hand done. I know in many cases many of the parts that have moved to the CNC machine have been done so because i'm terrified of using a machine called a shaper (A 5" tall, 3.5" diameter router spinning at 7500rpm).

- As a family (and a company), we have a policy that we will not alter the instrument for the sake of technology - I.e. we will not change the core design of the guitar for the sake of "fitting" it to a piece of technology for the sake of increased production.

— Source: Matthew Larrivée January 7, 2012

Larrivée History page on larrivee.com

Tobacco Sunburst

This is a wiki page. That means that you can edit it. If you prefer not to do that, please post suggestions in the Source: Discussion about acronyms on the Larrivée Forum

For more general Larrivée information see: Larrivée Guitars